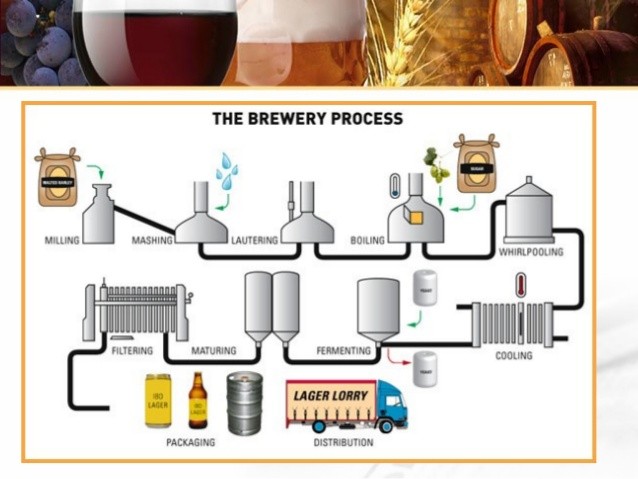

Application of refrigeration system in the production of beer, soft drinks:

Beer is food products in low-alcohol beverages, acquired by alcohol fermentation in low temperature room (from rice, corn, barley, barley etc…), water and flowers fur HUP. The beer production process undergoes several stages requiring new cooling needs.

For modern beer factories, cold is used in the specific stitch as follows:

Use the Quick cooling to room way after cooking

Translate sugar after the fur range temperature chemistry HUP 80oC requiring lower temperatures quickly down the fermentation temperature of 6đến8oC. Cooling speed of about 30đến45 minutes. If cooled slowly some harmful microorganisms strains for the fermentation process will catch up with the development and reduce the quality of the beer. To do the conditioning room the way people use the fast cooling device. That process is done through two stages:

-Use of water 1oC of the lower temperature of the room the way from 80oC to around 20oC.

-Use of glycol (or salt water) low temperature about-8oC to lower room temperature 20oC down the road from modern engineering 8oC use glycol to freezing because salt water cause corrosion damage to electrical equipment.

So in this cool down process requires the use of a fairly large amount of conditioning. Calculate the average for a brewery with capacity of 50 million liters per year per day must cooking about translation 180m3 road. The amount of conditioning used to cool down.

The process of beer fermentation

Beer fermentation process is done in a certain temperature range of about 6đến8oC. Fermentation is the stage decided to hop into the invoice lines translate metabolism of beer yeast under the action of active life through them. In the process of fermenting a solution of radiating a large amount of heat.

Sugar fermentation of hop culture took place over two stages:

-Primary fermentation: lasted from 7 to 12 days for the golden beer and 12 to 18 days for black beers. Fermentation temperature is 6 to 8oC.

-Secondary fermentation and storage: stretching for at least 3 weeks for all the beers. Extra fermentation temperature is 1 to 2° c.

The temperature influence to the fermentation process and product quality. When the high temperature will lead to the following effect:

+ Quick fermentation time.

+ Maximum density is higher when the temperature is low.

+ Ferment thoroughly but of the quadratic products (particularly diacetyl) create more.

+ Biomass generates more but the amount of dead cells back more and the declining speed of the technology also features more quickly.

+ The ratio between the electronic structure in beer beer quality, reducing balance

Every kind of yeast all have the appropriate temperature for the development of fermentation. When does not ensure the required temperature the results get the quality will be very poor.

Preservation and human-like glaze

An extremely important to cold in the brewery is stitched and human-like glaze. Men like to be preserved in the tank, especially at low temperatures. Tank also has a similar structure of fermentation tank, it has a cylindrical body outside has led cooling glycol coat. However the size of the smaller tank, Yeast fermentation tank a lot, so the amount of conditioning needed for the tank-like glaze.

For cooling CO2 East

In the fermentation process thanks to the hydrolysis process which in the fermentation tank out so much CO2. The process of CO2 generated in the reaction below.

The end result of the metabolic process (fermentation) from the hexoza etylic and gas cácbonic to alcohol can be represented by a general equation of Gay-Lussac as follows:

Very need for CO2 in beer technology process as at the stage of filling and handling technology in fermentation tank. The CO2 gas escapes from the fermentation tank in the chemical process need to be recovered, preserved for use in technology. To preserve the best CO2 can only in liquid, in normal temperature and pressure condensation of CO2 reached near 100at. So to reduce the pressure of CO2 preserved pressure down below 20 kG/cm2 need preservation temperature down to very low size-30-35oC.

Cooling water 1oC

Cold water is used in the brewery with many different purposes, especially used for fast cooling of the room the way after being turned to hop about 20oC. The use of water 1oC is a very effective and economical in the modern brewery. Heat load side of the scratch Cook according to time of day and irregular marks that are around. When the scratch Cook finish required to proceed very fast cooling. NET clearly if used directly, the cooling capacity of air conditioning would be very large.

The use of cold water 1oC to cold down fast room way permitting a considerable amount of conditioning to do conditioning room of the Cook quickly. This allows large cold system isn't necessary but still guarantee requirements. The water is cooled thanks to glycol to about 1oC over the fast cooling device type plate.

Cooling tunnel preservation tank fermented and conditioned

In some old technology plants, beer is cold preservation in the cooling tunnel, in this case need to provide cold to freezing tunnel maintenance.

Can use the conditioning of glycol to air conditioners in some certain areas of the plant, the flower preservation etc..

Application of refrigeration system in the production of beer, fresh water helps the process of production, storage, preservation and use are guaranteed safety and stability.